EagerLED LED Screen Quality Control

EagerLED has turned quality control of LED displays into a systematic process that spans the entire product lifecycle. From raw material procurement to production, from factory testing to after-sales service, strict standards are established at every stage, ensuring that customers receive only high-quality displays.

- Strict Product Performance Standards

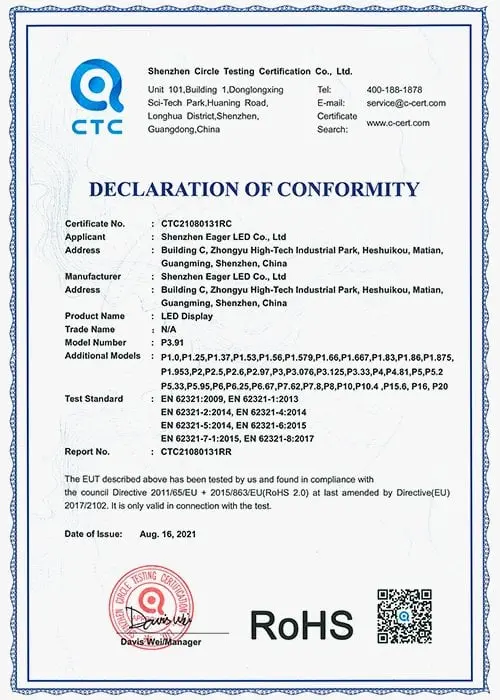

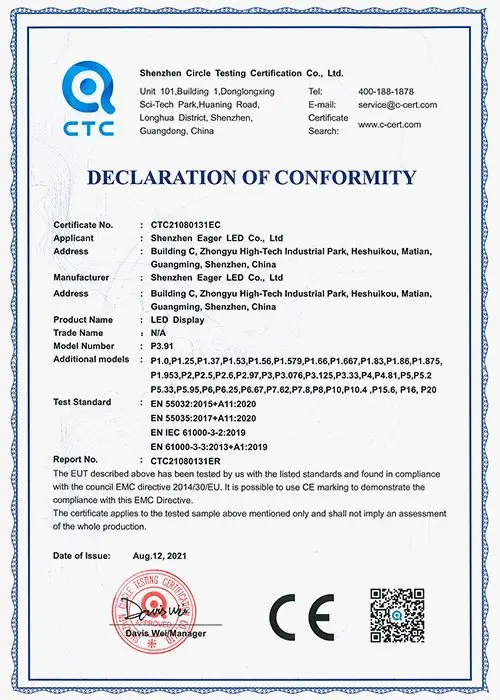

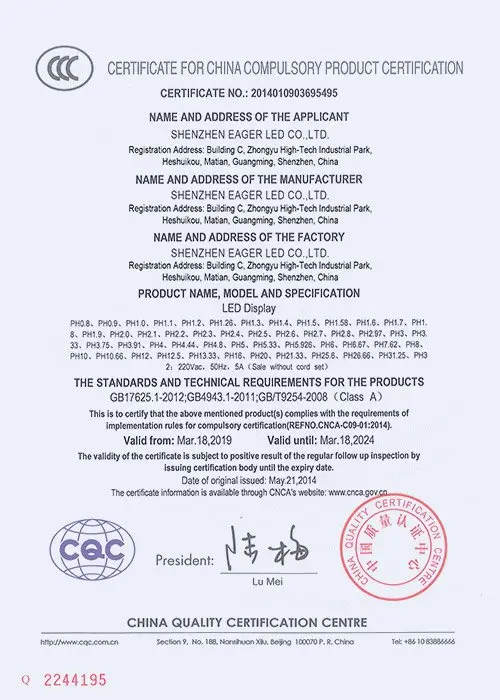

- Most Authoritative Quality Certifications

- Reliable and Worry-Free Shipping Services

The product our customers ultimately receive

The LED display screen provided by EagerLED will be clear during the day, not dazzling at night, with vivid and realistic colors, long-term use without damage, energy-saving and durable.

EagerLED LED Screen quality control system

Pre-production – strict material selection and plan formulation

- Material Selection: Strictly select high-consistency LED chips, high-temperature-resistant PCBs, high-refresh driver ICs, and other materials.

- Product Planning: Based on customer requirements, define key parameters such as screen size, resolution, and brightness, and develop a personalized solution.

- Detail Confirmation: Verify drawings, process standards, and BOM lists to avoid production errors and missing components.

During Production – Quality Control

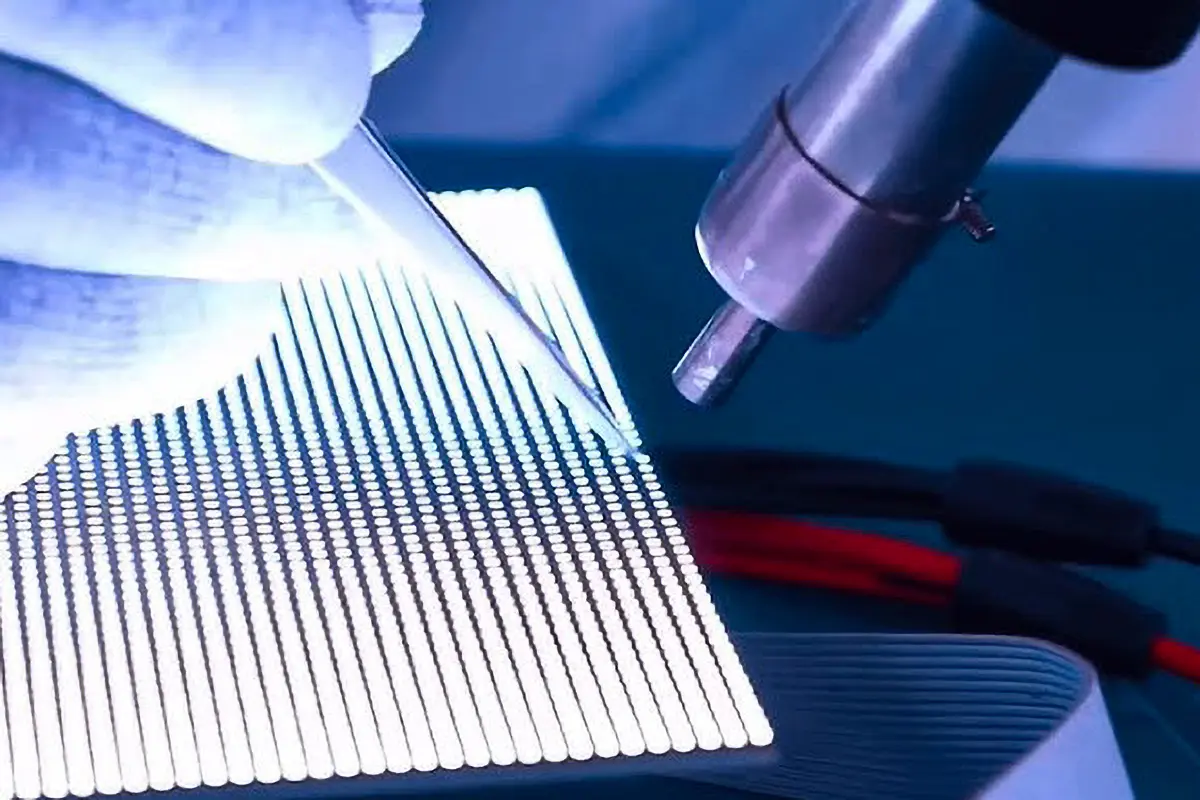

- SMT Placement: Fully automated placement + optical inspection, ensuring zero component offset and defect-free soldering.

- Module Assembly: Strict BIN mixing for color calibration + gel sealing, ensuring display consistency and waterproof/dustproof capabilities.

- Full Screen Assembly: High-precision cabinet calibration, achieving seamless splicing and flatness ≤ 0.5mm.

Post-production – Comprehensive Testing

- Optical Performance Testing: Manual point-by-point inspection of brightness and chromaticity uniformity.

- Aging Test: 72-hour high and low-temperature cycle testing (-20℃ ~ 50℃) to assess humidity and heat resistance.

- Functional Stability Testing: Continuous full-load operation for 48 hours to check dead pixel rate.

Packaging And Shipping

- Shockproof Packaging: Custom foam + wooden box protection/flight case, ensuring absolute shock resistance, compression resistance, and drop protection.

- Environmental Protection: Moisture-proof film + desiccant packaging, completely eliminating concerns about component moisture or oxidation due to temperature and humidity changes.