EagerLED display factory introduction

EagerLED was established in 2009 and has more than 16 years of experience in LED display production. The factory covers an area of more than 5,000 square meters and is equipped with more than 100 production personnel, forming a large production scale. Years of deep cultivation have enabled EagerLED to accumulate rich technology and industry experience, and can provide stable and reliable product support to global customers.

With a stable monthly output of 6,000+ square meters, EagerLED can not only ensure sufficient supply to meet the needs of large-volume orders, but also provide customers with fast and high-quality services.

16 years

lndustry Experience

100+

Production staff

5000+m²

Factory Area

6000+m²

Monthly production

2025 New LED Screen Price for You

Fill in the information and get your LED screen budget immediately!

Mature LED display industry chain

The manufacturing process of LED display screens is extremely complex. However, EagerLED has successfully overcome many technical difficulties with its outstanding technical strength and built a mature and complete industrial chain.

1. LED Lamp Baking

Using a dedicated bead oven to heat LED lights, removing internal stress and improving performance stability and durability.

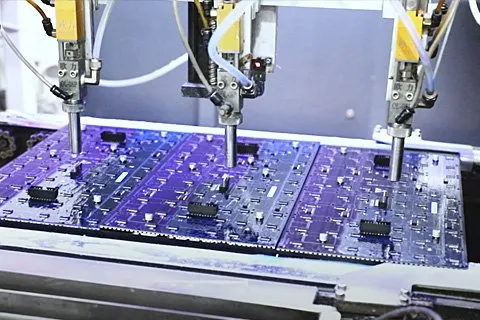

2. PCB SMT

Use advanced chip mounters and welding equipment to improve chip placement speed and accuracy, and quickly build a complete LED display circuit system.

3. LED SMT

Surface mount technology (SMT) enables precise mounting of electronic components such as LED lamps on printed circuit boards (PCBs).

4. Light on Test

Through the lighting test, check whether each LED lamp bead can work normally and whether there is any damage or defective condition.

5. Conformal Coating

The triple conformal lacquer forms a thin polymer film that can extend the service life of the LED module.

6. Install the Bottom Case

Assemble the PCB (Printed Circuit Board) with the bottom case using screws.

7. Glue waterproofing treatment

Glue filling materials (such as epoxy resin ab glue, ab silicone, etc.) can form a tough waterproof layer.

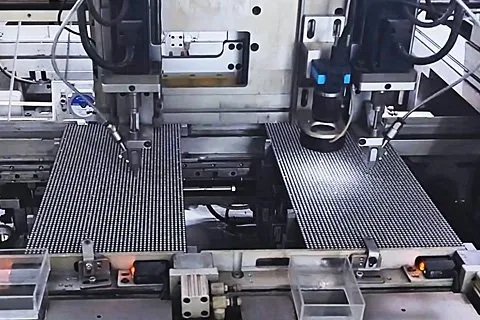

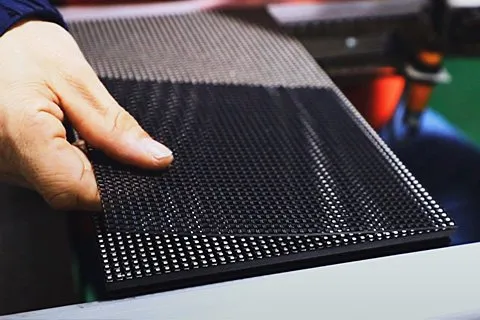

8. Install black mask

The black mask can reduce glare and improve the contrast and clarity of the LED display.

9. QC Test

QC Test is a comprehensive and meticulous process, involving multiple aspects of testing, such as appearance, brightness, color, and viewing angle evaluation.

10. Aging test

The LED module was subjected to a 12-hour aging test by simulating the actual usage environment.

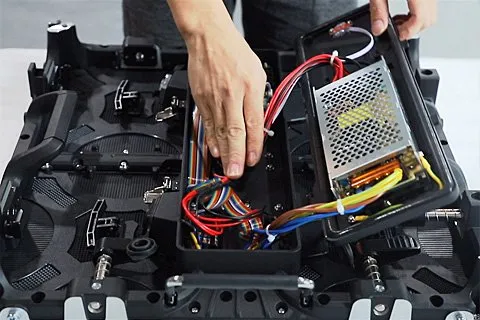

11. Cabinet Assembly

Assemble LED modules, frames, power supplies and other components into a complete single LED screen.

12. Screen aging test

The entire LED screen will undergo a 72-hour continuous operation test to conduct a preliminary assessment of stability and durability.

What benefits does EagerLED LED Screen Factory offer?

Choose EagerLED as your LED screen factory because we provide the following key advantages.

Advanced production equipment and technology: EagerLED LED Screen Factory boasts advanced equipment such as automatic glue dispensers, automatic crystal mounting machines, and automatic wire bonding machines. The production process is highly automated and intelligent.

Strong R&D and innovation capabilities: EagerLED has a professional R&D team, which is committed to the R&D and innovation of LED display technology, and has made significant breakthroughs in small pitch LED display technology and COB packaging technology.

Strict quality control: EagerLED has established a perfect quality management system, strict raw material testing, fine control of the production process, production environment testing, etc. Through these measures, we can ensure that the LED display products obtained by customers are stable and high-quality.

Rich product lines: EagerLED LED Screen Factory has a diverse product line, covering various types from indoor to outdoor, from fixed installation to rental, and can also provide customized services according to customer needs.

Customized service

Select EagerLED as your LED display manufacturing partner due to our distinctive and essential benefits.

Put on brand logo

EagerLED can provide personalized customization services for individuals or factories.

Private Customization

EagerLED puts your logo on display screens and packaging to showcase your brand.

Privacy Protection

Here you don’t need to worry about the security of your personal information, we will keep it strictly confidential.

Win-win cooperation

Using our products to promote your brand is also your recognition of us.